Hard Drawn Steel Wire

HARD DRAWN STEEL WIRE - CHEMICAL COMPOSITION, MASS % EN 10270-1:2011

| Chemical composition % | |||||||

| Designation | European Standard (EN) | C | Si | Mn | Max. P | Max. S | Max. Cu |

| SL | EN 10270-1 | 0.35 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.035 | 0.035 | 0.20 |

| SM | EN 10270-1 | 0.35 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.035 | 0.035 | 0.20 |

| SH | EN 10270-1 | 0.35 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.035 | 0.035 | 0.20 |

| DM | EN 10270-1 | 0.45 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.020 | 0.025 | 0.12 |

| DH | EN 10270-1 | 0.45 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.020 | 0.025 | 0.12 |

| CLASS II | DIN 17223:1964-1 | values not guaranteed | 0.030 | 0.030 | 0.12 | ||

Note- For diameters ≥ 1.6mm , the hard drawn steel wire can be supplied using patented or unpatented lead material.

APPROXIMATE EQUIVALENTS

| EUROPEAN | AMERICAN | JAPANESE | CHINESE | ||

| DESIGNATION | EN STANDARD | DIN | ASTM | G-3506 / G3522 | GB / T 4357 |

| SL | EN 10270-1 | CLASS A | A 227 | SWB | SL |

| SM | EN 10270-1 | CLASS B | A 227 | SWC | SM |

| SH | EN 10270-1 | CLASS C | A 228 | SWP-B | SH |

| DM | EN 10270-1 | - | A 227 | - | - |

| DH | EN 10270-1 | CLASS D | A 228 | SWP-B | DH |

| CLASS II | DIN 17223:1964-1 | CLASS II | - | - | - |

APPLICATION OF HARD DRAWN STEEL WIRE

| TYPE | Application of Hard Drawn Steel Wire |

| SL | Tension, compression or torsion springs that are chiefly subjected to low static stress. |

| SM | Tension, compression or torsion springs that are subjected to medium-high static stresses or, rarely, dynamic stresses. |

| DM | Tension, compression or torsion springs that are subjected to medium-high dynamic stresses. Also for wire shapes that require severe bending. |

| SH | Tension, compression or torsion springs that are subjected to high static stresses or moderately dynamic stresses. |

| DH | Tension, compression and torsion springs that are mainly submitted to high static strains and to medium levels of dynamic strains. |

| CLASS II | Compression springs, extension springs,and torsion springs for high and dynamic stresses. |

Types of wires for springs. Classed according to EN 10270-1:

| Tensile strength | Static conditions | Dynamic conditions |

| Low | SL | - |

| Medium | SM | DM |

| High | SH | DH |

MECHANICAL PROPERTIES AND QUALITY REQUIREMENTS OF THE SL, SM, DM, SH AND DH STEEL WIRE TYPES EN 10270-1

| Diameter of the wire d | Tensile strength Rm For steel wires of the type | CLASS II (approx.) 1) | Minimum area reduction after Z break for SL, SM, SH, DM and DH wire types | ||||

| Nominal value mm | SL | SM | DM | SH | DH e | ||

| MPa | MPa | MPa | MPa | MPa | % | ||

| d = 0.05 | - | - | - | - | 2800 - 3520 | ||

| 0.05 < d ≤ 0.06 | - | - | - | - | 2800 - 3520 | ||

| 0.06 < d ≤ 0.07 | - | - | - | - | 2800 - 3520 | ||

| 0.07 < d ≤ 0.08 | - | - | - | - | 2800 - 3480 | ||

| 0.08 < d ≤ 0.09 | - | - | - | - | 2800 - 3430 | ||

| 0.09 < d ≤ 0.10 | - | - | - | - | 2800 - 3380 | ||

| 0.10 < d ≤ 0.11 | - | - | - | - | 2800 - 3350 | ||

| 0.11 < d ≤ 0.12 | - | - | - | - | 2800 - 3320 | 2700 - 3090 | |

| 0.12 < d ≤ 0.14 | - | - | - | - | 2800 - 3250 | ||

| 0.14 < d ≤ 0.16 | - | - | - | - | 2800 - 3200 | ||

| 0.16 < d ≤ 0.18 | - | - | - | - | 2800 - 3160 | ||

| 0.18 < d ≤ 0.20 | - | - | - | - | 2800 - 3110 | ||

| 0.20 < d ≤ 0.22 | - | - | - | - | 2770 - 3080 | ||

| 0.22 < d ≤ 0.25 | - | - | - | - | 2770 - 3010 | ||

| 0.25 < d ≤ 0.28 | - | - | - | - | 2680 - 2970 | ||

| 0.28 < d ≤ 0.30 | - | 2370 - 2650 | 2370 - 2650 | 2660 - 2940 | 2660 - 2940 | ||

| 0.30 < d ≤ 0.32 | - | 2350 - 2630 | 2350 - 2630 | 2640 - 2920 | 2640 - 2920 | ||

| 0.32 < d ≤ 0.34 | - | 2330 - 2600 | 2330 - 2600 | 2610 - 2890 | 2610 - 2890 | ||

| 0.34 < d ≤ 0.36 | - | 2310 - 2580 | 2310 - 2580 | 2590 - 2870 | 2590 - 2870 | 2650 - 3040 | |

| 0.36 < d ≤ 0.38 | - | 2290 - 2560 | 2290 - 2560 | 2570 - 2850 | 2570 - 2850 | ||

| 0.38 < d ≤ 0.40 | - | 2270 - 2550 | 2270 - 2550 | 2560 - 2830 | 2560 - 2830 | ||

| 0.40 < d ≤ 0.43 | - | 2250 - 2520 | 2250 - 2520 | 2530 - 2800 | 2530 - 2800 | ||

| 0.43 < d ≤ 0.45 | - | 2240 - 2500 | 2240 - 2500 | 2510 - 2780 | 2510 - 2780 | ||

| 0.45 < d ≤ 0.48 | - | 2220 - 2480 | 2220 - 2480 | 2490 - 2760 | 2490 - 2760 | 2650 - 2940 | |

| 0.48 < d ≤ 0.50 | - | 2200 - 2470 | 2200 - 2470 | 2480 - 2740 | 2480 - 2740 | ||

| 0.50 < d ≤ 0.53 | - | 2180 - 2450 | 2180 - 2450 | 2460 - 2720 | 2460 - 2720 | ||

| 0.53 < d ≤ 0.56 | - | 2170 - 2430 | 2170 - 2430 | 2440 - 2700 | 2440 - 2700 | ||

| 0.56 < d ≤ 0.60 | - | 2140 - 2400 | 2140 - 2400 | 2410 - 2670 | 2410 - 2670 | ||

| 0.60 < d ≤ 0.63 | - | 2130 - 2380 | 2130 - 2380 | 2390 - 2650 | 2390 - 2650 | 2550 - 2840 | |

| 0.63 < d ≤ 0.65 | - | 2120 - 2370 | 2120 - 2370 | 2380 - 2640 | 2380 - 2640 | ||

| 0.65 < d ≤ 0.70 | - | 2090 - 2350 | 2090 - 2350 | 2360 - 2610 | 2360 - 2610 | ||

| 0.70 < d ≤ 0.75 | - | 2070 - 2320 | 2070 - 2320 | 2330 - 2580 | 2330 - 2580 | ||

| 0.75 < d ≤ 0.80 | - | 2050 - 2300 | 2050 - 2300 | 2310 - 2560 | 2310 - 2560 | 40 | |

| 0.80 < d ≤ 0.85 | - | 2030 - 2280 | 2030 - 2280 | 2290 - 2530 | 2290 - 2530 | 2500 - 2800 | 40 |

| 0.85 < d ≤ 0.90 | - | 2010 - 2260 | 2010 - 2260 | 2270 - 2510 | 2270 - 2510 | 40 | |

| 0.90 < d ≤ 0.95 | - | 2000 - 2240 | 2000 - 2240 | 2250 - 2490 | 2250 - 2490 | 40 | |

| 0.95 < d ≤ 1.00 | 1720 - 1970 | 1980 - 2220 | 1980 - 2220 | 2230 - 2470 | 2230 - 2470 | 40 | |

| 1.00 < d ≤ 1.05 | 1710 - 1950 | 1960 - 2200 | 1960 - 2200 | 2210 - 2450 | 2210 - 2450 | 2450 - 2750 | 40 |

| 1.05 < d ≤ 1.10 | 1690 - 1940 | 1950 - 2190 | 1950 - 2190 | 2200 - 2430 | 2200 - 2430 | 40 | |

| 1.10 < d ≤ 1.20 | 1670 - 1910 | 1920 - 2160 | 1920 - 2160 | 2170 - 2400 | 2170 - 2400 | 40 | |

| 1.20 < d ≤ 1.25 | 1660 - 1900 | 1910 - 2140 | 1910 - 2140 | 2150 - 2380 | 2150 - 2380 | 40 | |

| 1.25 < d ≤ 1.30 | 1640 - 1890 | 1900 - 2130 | 1900 - 2130 | 2140 - 2370 | 2140 - 2370 | 2350 - 2650 | 40 |

| 1.30 < d ≤ 1.40 | 1620 - 1860 | 1870 - 2100 | 1870 - 2100 | 2110 - 2340 | 2110 - 2340 | 40 | |

| 1.40 < d ≤ 1.50 | 1600 - 1840 | 1850 - 2080 | 1850 - 2080 | 2090 - 2310 | 2090 - 2310 | 40 | |

| 1.50 < d ≤ 1.60 | 1590 - 1820 | 1830 - 2050 | 1830 - 2050 | 2060 - 2290 | 2060 - 2290 | 2260 - 2500 | 40 |

| 1.60 < d ≤ 1.70 | 1570 - 1800 | 1810 - 2030 | 1810 - 2030 | 2040 - 2260 | 2040 - 2260 | 40 | |

| 1.70 < d ≤ 1.80 | 1550 - 1780 | 1790 - 2010 | 1790 - 2010 | 2020 - 2240 | 2020 - 2240 | 2210 - 2450 | 40 |

| 1.80 < d ≤ 1.90 | 1540 - 1760 | 1770 - 1990 | 1770 - 1990 | 2000 - 2220 | 2000 - 2220 | 40 | |

| 1.90 < d ≤ 2.00 | 1520 - 1750 | 1760 - 1970 | 1760 - 1970 | 1980 - 2200 | 1980 - 2200 | 2110 - 2350 | 40 |

| 2.00 < d ≤ 2.10 | 1510 - 1730 | 1740 - 1960 | 1740 - 1960 | 1970 - 2180 | 1970 - 2180 | 40 | |

| 2.10 < d ≤ 2.25 | 1490 - 1710 | 1720 - 1930 | 1720 - 1930 | 1940 - 2150 | 1940 - 2150 | 40 | |

| 2.25 < d ≤ 2.40 | 1470 - 1690 | 1700 - 1910 | 1700 - 1910 | 1920 - 2130 | 1920 - 2130 | - | 40 |

| 2.40 < d ≤ 2.50 | 1460 - 1680 | 1690 - 1890 | 1690 - 1890 | 1900 - 2110 | 1900 - 2110 | 40 | |

| 2.50 < d ≤ 2.60 | 1450 - 1660 | 1670 - 1880 | 1670 - 1880 | 1890 - 2100 | 1890 - 2100 | 40 | |

| 2.60 < d ≤ 2.80 | 1420 - 1640 | 1650 - 1850 | 1650 - 1850 | 1860 - 2070 | 1860 - 2070 | - | 40 |

| 2.80 < d ≤ 3.00 | 1410 - 1620 | 1630 - 1830 | 1630 - 1830 | 1840 - 2040 | 1840 - 2040 | - | 40 |

| 3.00 < d ≤ 3.20 | 1390 - 1600 | 1610 - 1810 | 1610 - 1810 | 1820 - 2020 | 1820 - 2020 | - | 40 |

| 3.20 < d ≤ 3.40 | 1370 - 1580 | 1590 - 1780 | 1590 - 1780 | 1790 - 1990 | 1790 - 1990 | - | 40 |

| 3.40 < d ≤ 3.60 | 1350 - 1560 | 1570 - 1760 | 1570 - 1760 | 1770 - 1970 | 1770 - 1970 | - | 40 |

| 3.60 < d ≤ 3.80 | 1340 - 1540 | 1550 - 1740 | 1550 - 1740 | 1750 - 1950 | 1750 - 1950 | - | 40 |

| 3.80 < d ≤ 4.00 | 1320 - 1520 | 1530 - 1730 | 1530 - 1730 | 1740 - 1930 | 1740 - 1930 | - | 35 |

| 4.00 < d ≤ 4.25 | 1310 - 1500 | 1510 - 1700 | 1510 - 1700 | 1710 - 1900 | 1710 - 1900 | - | 35 |

| 4.25 < d ≤ 4.50 | 1290 - 1490 | 1500 - 1680 | 1500 - 1680 | 1690 - 1880 | 1690 - 1880 | - | 35 |

| 4.50 < d ≤ 4.75 | 1270 - 1470 | 1480 - 1670 | 1480 - 1670 | 1680 - 1860 | 1680 - 1860 | - | 35 |

| 4.75 < d ≤ 5.00 | 1260 - 1450 | 1460 - 1650 | 1460 - 1650 | 1660 - 1840 | 1660 - 1840 | - | 35 |

| 5.00 < d ≤ 5.30 | 1240 - 1430 | 1440 - 1630 | 1440 - 1630 | 1640 - 1820 | 1640 - 1820 | - | 35 |

| 5.30 < d ≤ 5.60 | 1230 - 1420 | 1430 - 1610 | 1430 - 1610 | 1620 - 1800 | 1620 - 1800 | - | 35 |

| 5.60 < d ≤ 6.00 | 1210 - 1390 | 1400 - 1580 | 1400 - 1580 | 1590 - 1770 | 1590 - 1770 | - | 35 |

| 6.00 < d ≤ 6.30 | 1190 - 1380 | 1390 - 1560 | 1390 - 1560 | 1570 - 1750 | 1570 - 1750 | - | 35 |

| 6.30 < d ≤ 6.50 | 1180 - 1370 | 1380 - 1550 | 1380 - 1550 | 1560 - 1740 | 1560 - 1740 | - | 35 |

| 6.50 < d ≤ 7.00 | 1160 - 1340 | 1350 - 1530 | 1350 - 1530 | 1540 - 1710 | 1540 - 1710 | - | 35 |

| 7.00 < d ≤ 7.50 | 1140 - 1320 | 1330 - 1500 | 1330 - 1500 | 1510 - 1680 | 1510 - 1680 | - | 30 |

| 7.50 < d ≤ 8.00 | 1120 - 1300 | 1310 - 1480 | 1310 - 1480 | 1490 - 1660 | 1490 - 1660 | - | 30 |

| 8.00 < d ≤ 8.50 | 1110 - 1280 | 1290 - 1460 | 1290 - 1460 | 1470 - 1630 | 1470 - 1630 | - | 30 |

| 8.50 < d ≤ 9.00 | 1090 - 1260 | 1270 - 1440 | 1270 - 1440 | 1450 - 1610 | 1450 - 1610 | - | 30 |

| 9.00 < d ≤ 9.50 | 1070 - 1250 | 1260 - 1420 | 1260 - 1420 | 1430 - 1590 | 1430 - 1590 | - | 30 |

| 9.50 < d ≤ 10.00 | 1060 - 1230 | 1240 - 1400 | 1240 - 1400 | 1410 - 1570 | 1410 - 1570 | - | 30 |

| 10.00 < d ≤ 10.50 | - | 1220 - 1380 | 1220 - 1380 | 1390 - 1550 | 1390 - 1550 | - | 30 |

| 10.50 < d ≤ 11.00 | - | 1210 - 1370 | 1210 - 1370 | 1380 - 1530 | 1380 - 1530 | - | 30 |

| 11.00 < d ≤ 12.00 | - | 1180 - 1340 | 1180 - 1340 | 1350 - 1500 | 1350 - 1500 | - | 30 |

| 12.00 < d ≤ 12.50 | - | 1170 - 1320 | 1170 - 1320 | 1130 - 1480 | 1130 - 1480 | - | 28 |

| 12.50 < d ≤ 13.00 | - | 1160 - 1310 | 1160 - 1310 | 1320 - 1470 | 1320 - 1470 | - | 28 |

| 13.00 < d ≤ 14.00 | - | 1130 - 1280 | 1130 - 1280 | 1290 - 1440 | 1290 - 1440 | - | 28 |

| 14.00 < d ≤ 15.00 | - | 1160 - 1260 | 1160 - 1260 | 1270 - 1410 | 1270 - 1410 | - | 28 |

| 15.00 < d ≤ 16.00 | - | 1090 - 1230 | 1090 - 1230 | 1240 - 1390 | 1240 - 1390 | - | 28 |

| 16.00 < d ≤ 17.00 | - | 1070 - 1210 | 1070 - 1210 | 1220 - 1360 | 1220 - 1360 | - | 28 |

| 17.00 < d ≤ 18.00 | - | 1050 - 1190 | 1050 - 1190 | 1200 - 1340 | 1200 - 1340 | - | 28 |

| 18.00 < d ≤ 19.00 | - | 1030 - 1170 | 1030 - 1170 | 1180 - 1320 | 1180 - 1320 | - | 28 |

| 19.00 < d ≤ 20.00 | - | 1020 - 1150 | 1020 - 1150 | 1160 - 1300 | 1160 - 1300 | - | 28 |

1) The values listed in DIN 17223:1964 were given in kg/mm2; the conversion performed is for guidance purposes.

PERMISSIBLE TENSILE STRENGTH RANGE (MPa) IN A SINGLE PACKAGE EN 10270-1:2011

| Nominal diameter d mm | SL, SM, SH | DM, DH |

| d < 0.80 | 150 | 150 |

| 0.80 ≤ d < 1.60 | 120 | 100 |

| 1.60 ≤ d | 120 | 70 |

The requirements are applicable to unit packages in which the mass in kilogrammes is not greater than the value 250 x d (d = wire diameter in mm) or a value of 1000 kg. In the case of coils with a higher mass, appropriate arrangements must be agreed.

Coatings subject to Standards:

| Coating | Description | |

| Phosphated | ph | The wire is treated in a solution so that a layer of phosphated metal forms on its surface. |

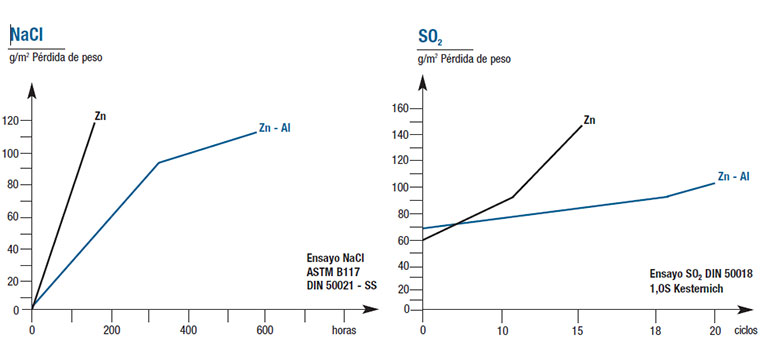

| Galvanising | Z | The surface is coated in a layer of zinc. |

| Zinc - Aluminium | ZA | The surface is coated in a layer of Zn 95 / Al 5(%) |

| Reddish | rd | The surface is coated with a thin layer of copper, normally a conversion coating. |

| Coppery | Cu | The surface is coated in a thick (even) layer of copper |

MINIMUM COATING DENSITY REQUIRED OF ZINC OR ZINC/ALUMINIUM EN 10270-1

| Nominal diameter d mm | Minimum coating density a) b) g/m² |

| 0.20 ≤ d < 0.25 | 20 |

| 0.25 ≤ d < 0.40 | 25 |

| 0.40 ≤ d < 0.50 | 30 |

| 0.50 ≤ d < 0.60 | 35 |

| 0.60 ≤ d < 0.70 | 40 |

| 0.70 ≤ d < 0.80 | 45 |

| 0.80 ≤ d < 0.90 | 50 |

| 0.90 ≤ d < 1.00 | 55 |

| 1.00 ≤ d < 1.20 | 60 |

| 1.20 ≤ d < 1.40 | 65 |

| 1.40 ≤ d < 1.65 | 70 |

| 1.65 ≤ d < 1.85 | 75 |

| 1.85 ≤ d < 2.15 | 80 |

| 2.15 ≤ d < 2.50 | 85 |

| 2.50 ≤ d < 2.80 | 95 |

| 2.80 ≤ d < 3.20 | 100 |

| 3.20 ≤ d < 3.80 | 105 |

| 3.80 ≤ d < 10.00 | 110 |

a) The requirements regarding zinc coatings fall within class C in Standard EN 10244-2:2009.

b) If different coating weights are required, priority will be given to the reference coating weights established in Standard En 10244-2 (for example: class D of standard En 10244-2:2009).

SALT SPRAY TEST

| GALVANISED COATING | Zn - Al COATING | ||

| Exposure time (hours) | Density of Zn (g/m2) | Exposure time (hours) | Density of Zn - Al (g/m2) |

| 36 | 80 | - | - |

| 48 | 90 | 120 | >40 |

| 72 | 105 | 240 | >60 |

| 96 | 125 | 264 | >75 |

| 120 | 165 | 288 | >85 |

| 144 | 195 | 312 | >100 |

| 168 | 220 | 360 | >110 |

| 192 | 240 | 408 | >125 |

Diameter tolerances. Permissible deviations according to EN 10270-1

| Diameter of the wire d | |

| Nominal value mm | Permissible deviations mm |

| 0.05 < d ≤ 0.09 | ± 0.003 |

| 0.09 < d ≤ 0.16 | ± 0.004 |

| 0.16 < d ≤ 0.25 | ± 0.005 |

| 0.25 < d ≤ 0.63 | ± 0.008 |

| 0.63 < d ≤ 0.75 | ± 0.010 |

| 0.75 < d ≤ 1.00 | ± 0.015 |

| 1.00 < d ≤ 1.20 | ± 0.020 |

| 1.20 < d ≤ 1.70 | ± 0.020 |

| 1.70 < d ≤ 2.60 | ± 0.025 |

| 2.60 < d ≤ 4.00 | ± 0.030 |

| 4.00 < d ≤ 5.30 | ± 0.035 |

| 5.30 < d ≤ 7.00 | ± 0.040 |

| 7.00 < d ≤ 9.00 | ± 0.045 |

| 9.00 < d ≤ 10.00 | ± 0.050 |

| 10.00 < d ≤ 11.00 | ± 0.070 |

| 11.00 < d ≤ 14.00 | ± 0.080 |

| 14.00 < d ≤ 18.00 | ± 0.090 |

| 18.00 < d ≤ 20.00 | ± 0.100 |

OVALITY

WHEN SUPPLIED IN RODS. Straightened wire:

| Nominal diameter d mm | Diameter tolerance a) mm | Supply capacity b) mm. | ||

| Lower tolerance | Higher tolerance | Minimum length | Maximum length | |

| 0.65 ≤ d < 0.80 | -0.010 | +0.022 | 50 | 2000 |

| 0.80 ≤ d < 1.01 | -0.015 | +0,030 | 30 | 2000 |

| 1.01 ≤ d < 1.35 | -0.020 | +0,040 | ||

| 1.35 ≤ d < 1.78 | -0.020 | +0,045 | ||

| 1.78 ≤ d < 2.01 | -0.025 | +0,055 | ||

| 2.01 ≤ d < 2.35 | -0.025 | +0,060 | 30 | 4000 |

| 2.35 ≤ d < 2.78 | -0.025 | +0,065 | ||

| 2.78 ≤ d < 3.01 | -0.030 | +0,075 | ||

| 3.01 ≤ d < 3.35 | -0.030 | +0,080 | 30 | 4000 |

| 3.35 ≤ d < 4.01 | -0.030 | +0,090 | ||

| 4.01 ≤ d < 4.35 | -0.035 | +0,100 | ||

| 4.35 ≤ d < 5.01 | -0.035 | +0,110 | 30 | 4350 |

| 5.01 ≤ d < 5.45 | -0.035 | +0,120 | ||

| 5.45 ≤ d < 6.01 | -0.040 | +0,130 | ||

| 6.01 ≤ d < 7.12 | -0.040 | +0.150 | 250 | 4350 |

| 7.12 ≤ d < 7.67 | -0.045 | +0,160 | ||

| 7.67 ≤ d < 9.01 | -0.045 | +0,180 | ||

| 9.01 ≤ d < 10.01 | -0.050 | +0,200 | ||

| 10.01 ≤ d < 10.50 | -0.070 | +0,240 | ||

a) Diameter tolerances of straightened and cut lengths according to EN 10270-1

b) Approximate data for information purposes.

STANDARD LENGTH TOLERANCES

| NOMINAL LENGTH | TOLERANCE |

| L < = 1000 mm. | +/- 1 mm. |

| 1000 < L < = 4000 | - 0mm. / +3 mm. |

The WIROLL project with file number (ZL-2023/00561) has obtained support from the Hazitek...

The WIROLL project with file number (ZL-2023/00561) has obtained support from the Hazitek...